A revolutionary system, an automated process which eliminates all margins of error and speeds up manufacturing times.

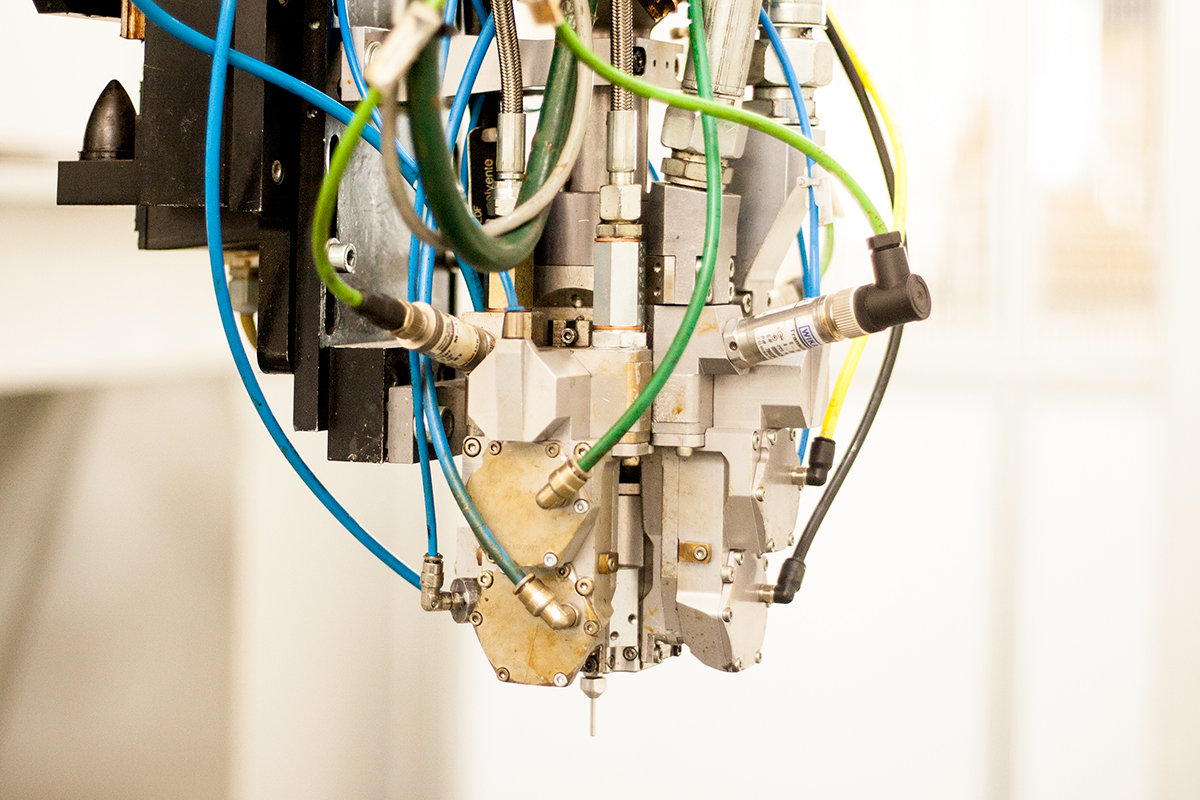

Gienne Plast, thanks to an absolutely innovative machine, can create foam gaskets and take care of potting and encapsulation. And this is done with a completely automated system which mixes the components and lays the material (be it adhesive, resin or plastic) directly on the profiles of the work pieces. The precision and speed with which plastic materials can be handled (high, medium and low viscosity) makes it possible to achieve exceptional results using a safe and very intuitive process.

This method makes it possible to reach absolute quality standards in terms of durability and precision, greatly exceeding the results normally guaranteed by traditional processing systems.

The type of compound used and the laying methods ensure a very effective sealing of the parts and perfect isolation for greater resistance over time or against external agents.

Gaskets, encapsulation and potting are not only carried out much more quickly, even on complex profiles, but their performance is also greatly enhanced thanks to a process technique currently being patented.