Injection moulding for plastics

Quick creation of prototypes and production pieces

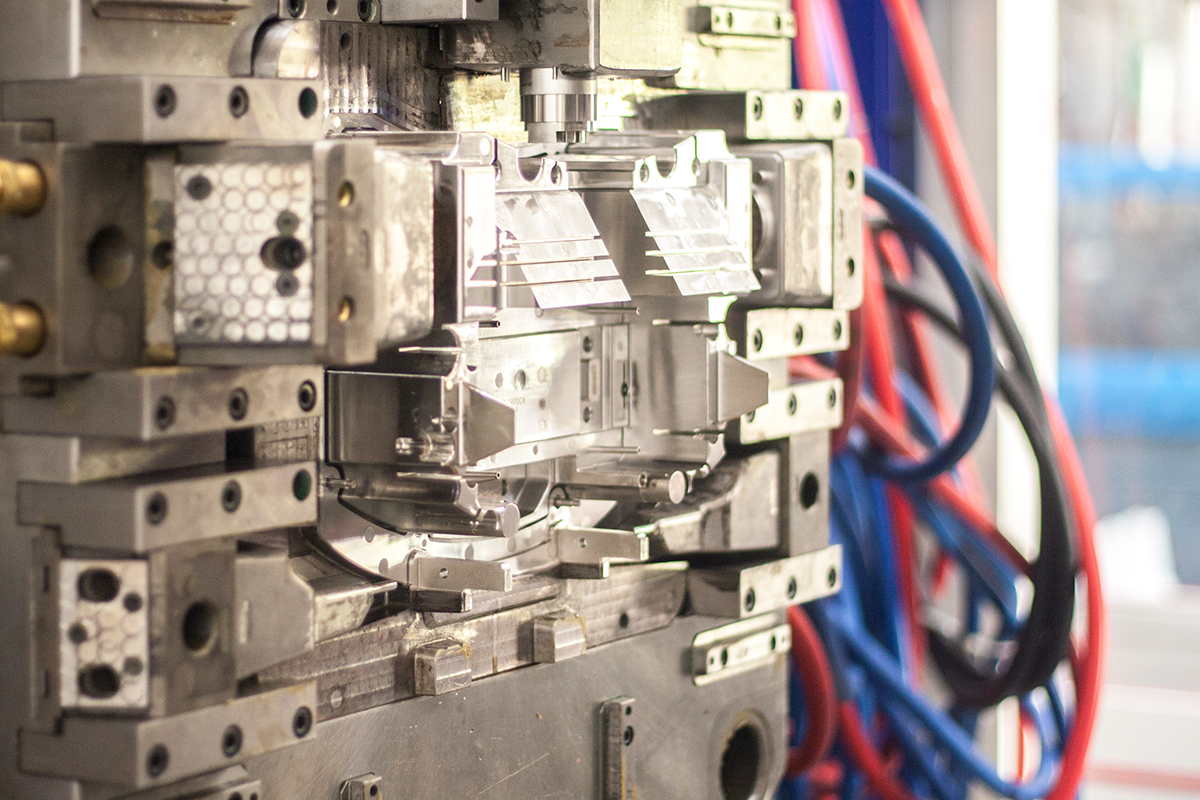

The plastic injection moulding process consists in melting plastic pellets (polymers/thermoplastics) until the material is soft enough to be pressure injected into the cavity of the mould and fill it. Here it then solidifies to create the end product.

Injection moulding, as a process driven by technology which leverages on production automation, is one of the manufacturing processes which most characterises Gienne Plast.

The company has a wide selection of machines, 16 to be exact, ranging from 30 - 900 tonnes. Their size and different functions allow us to work on products made from different materials and of weights ranging from 0.01 g to 4.5 kg.

Gienne Plast's injection moulding of thermoplastics is a standard process which uses steel or aluminium moulds. This procedure allows the mould operators to monitor the filling pressure and the appearance and basic quality of the manufactured products. Furthermore, it is a quick and efficient system from an economic and productive point of view.